HYUNDAI CORPORATION GROUP acquires a minority stake in technology company FLAXRES GmbH, thereby establishing a strategic partnership for significant non-European markets. The acquisition of the minority stake confirms a valuation of FLAXRES in the triple-digit million range.

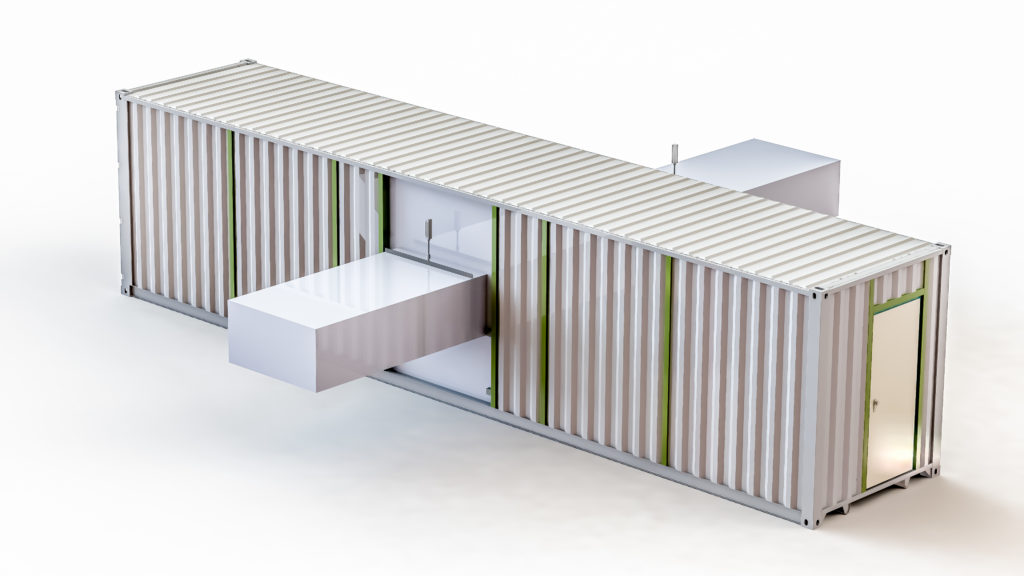

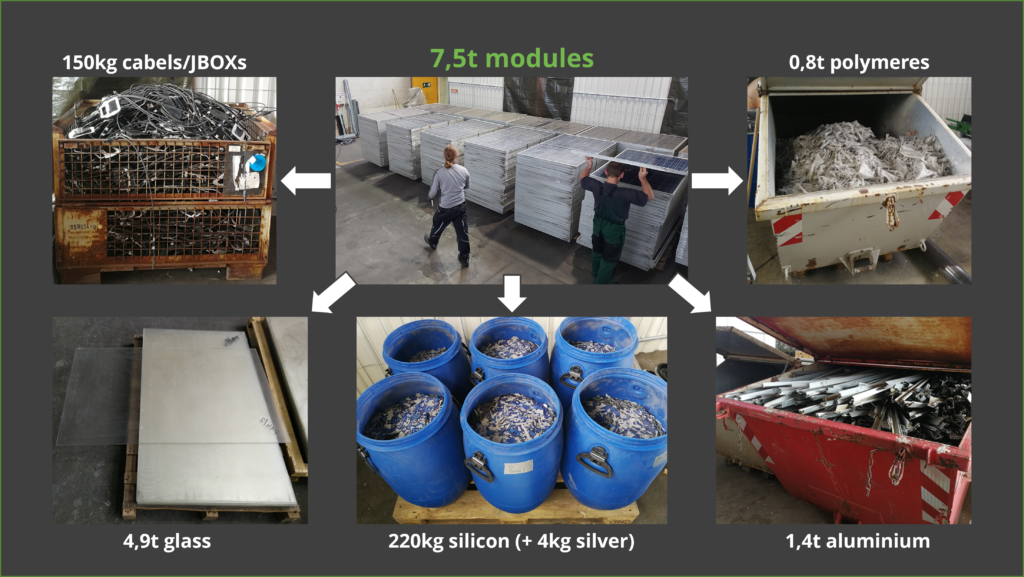

FLAXRES is part of econnext Group and specializes in the development of environmentally friendly recycling solutions for photovoltaic modules. The technology developed and patented by FLAXRES is based on short-term high-temperature heating using flash lamps, or “flash lamp annealing”, and is not only substantially more environmentally friendly, but also more cost-efficient and considerably faster than conventional processes which are usually based on mechanical shredding or thermal recycling (pyrolysis) of the panels.

The process developed by FLAXRES offers a solution to one of the most pressing challenges facing the renewable energy sector in the coming years. Many modules that were installed during the first wave of solar energy expansion have now reached the end of their life cycle, with no environmentally friendly and efficient processes for a true circular economy solution available. With the method developed by FLAXRES all composite materials are cleanly separated and the extracted resources are of such a high quality that they can be profitably returned to the material cycle.

The two founders of FLAXRES and its parent company FLAXTEC, Michael Rudolf Heuschkel and Dr Harald Gross, have been working on the technology since mid-2016. Following the successful application of the process in the test phase, FLAXRES is now working with renowned companies in the recycling industry.

Together with the HYUNDAI CORPORATION GROUP, FLAXRES will expand internationally and apply the FLAXRES technology in selected markets to feed end-of-life PV modules into the global circular economy.

“We are delighted that we have been able to find a major strategic investor and partner for our technological solution, with whom we will jointly develop global markets.”, say Michael Rudolf Heuschkel and Dr Harald Gross.

econnext AG, as the majority shareholder of FLAXTEC GmbH (the parent company of FLAXRES GmbH) also very much welcomes the new strategic partner and looks forward to the future together.

Michael Schneider, Co-Founder and Co-CEO of econnext: “The technology that the founders of FLAXTEC and FLAXRES have developed is groundbreaking and finally offers a way to recycle PV modules in an environmentally friendly and efficient way – together with our Korean partner, we can develop international markets considerably faster and better, thereby contributing to addressing one of the major criticisms of renewable energies.”

econnext

econnext AG is a cleantech holding company founded in 2016 and is exclusively dedicated to supporting subsidiaries that have a long-term, profitable and scalable positive impact on the economy, environment and society in line with the United Nations Sustainable Development Goals (SDGs).

In addition to FLAXTEC, the econnext subsidiaries include Circular Carbon GmbH in Hamburg (biochar for soil improvement and as a carbon sink), ESG Screen17 GmbH in Frankfurt (sustainability screening of investment portfolios), Autarq GmbH in Prenzlau (solar roof tiles), GRIPS Energy GmbH in Berlin (renewable/ solar energy supply) and LUMENION GmbH in Berlin (large-scale energy storage/heat storage), as well as a minority stake in ambibox GmbH in Mainz (decentralized energy systems and charging technology).

www.econnext.eu